Our technical solutions

The complete automation process consists of six steps . Of these, GrabMax supports digitisation and the introduction of innovative technologies through machine vision integration and robot programming .

Electrical design

Machine vision

Safety

Mechanical design

Robot programming

PLC programming

Electrical design

Machine vision

Safety

Mechanical design

Robot programming

PLC programming

Topology

The GrabMax robotic solution consists of four main parts:

- the camera is responsible for taking the image

- the vision controller runs the GrabMax platform , on which the module handles and processes the image from the camera and defines the path for the robot

- the robot controller receives the task to be performed via a communication interface

- the movement of the robot arm is controlled by this robot controller

GrabMax

Camera, scanner

Vision controller

TCP IP

GrabMax platform

GrabMax

Camera, scanner

Vision controller

TCP IP

GrabMax platform

Robot

Robot

Robot controller

Robot controller

Robot

GrabMax products

Vision controller

The vision controller communicates with the robot controller over PROFINET, EtherNet/IP or TCP. The GrabMax system supports both six-axis industrial and collaborative robots (Fanuc, Yaskawa, UR, KUKA, Doosan, etc.).

GrabMax platform

Bin picking

Automatic unloading of containers

- 100% efficiency

- for randomly arranged objects

- for items with different optical properties

- avoiding collisions

- object recognition and sorting

Quality control

Automatic quality control

- high reliability 3D point cloud and CAD model

- automatically removes defective elements from the manufacturing process

- items can be classified into several categories based on quality

- easily administered, clear defect reports

- yields more accurate results than the human eye

Pallet unpacking

Automatic unloading of pallets

- boxes, packages, crates, drums of various shapes and sizes

- simple software configuration without programming

- unloading pallets of different standards

- sorting and relocation of different types of packages

- fully automatic and semi-automatic options

Machine tending

Automatic loading of machines

- the machines are loaded evenly and continuously by the robots

- reliable, accurate and safe solution

- reduces the need for human resources and the risk of accidents

- can be used for simultaneous loading of several machines

- with the bin picking solution, the item can be selected and loaded immediately

AI

Artificial Intelligence

- automatic object recognition

- rapid annotation

- precise location and error detection

- production tracking and control

- automatic decision-making based on artificial intelligence

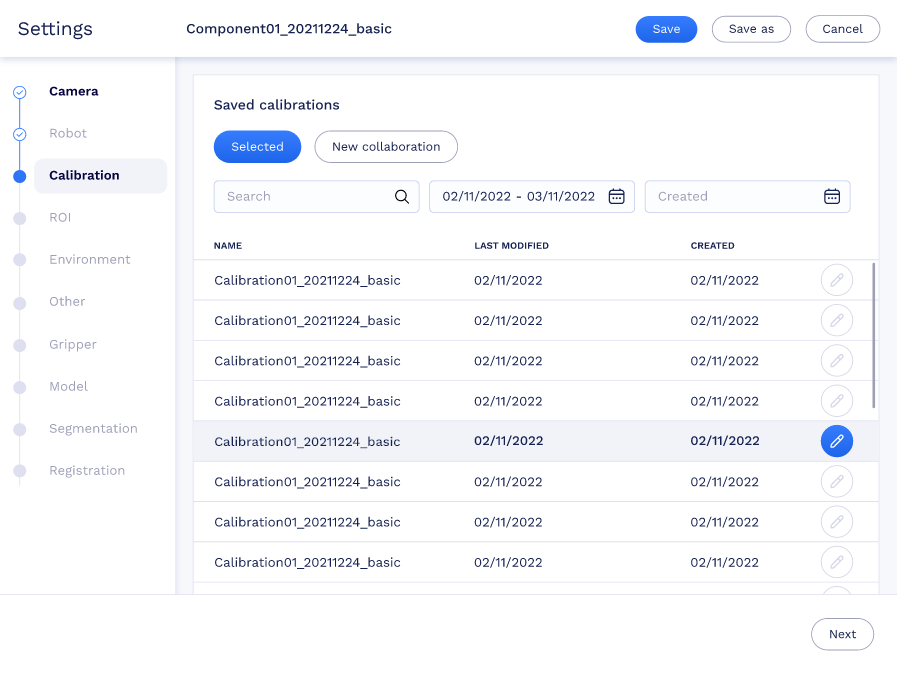

Platform

The platform can be easily configured for a specific task in the corresponding module. The process is guided from start to finish and can be set up step by step.

Connectable cameras and scanners

Depending on the task, the camera can be 2D, 3D, monochrome, RGB, depth or laser scanner.

Meet our GrabMax solutions!

Request a free consultation